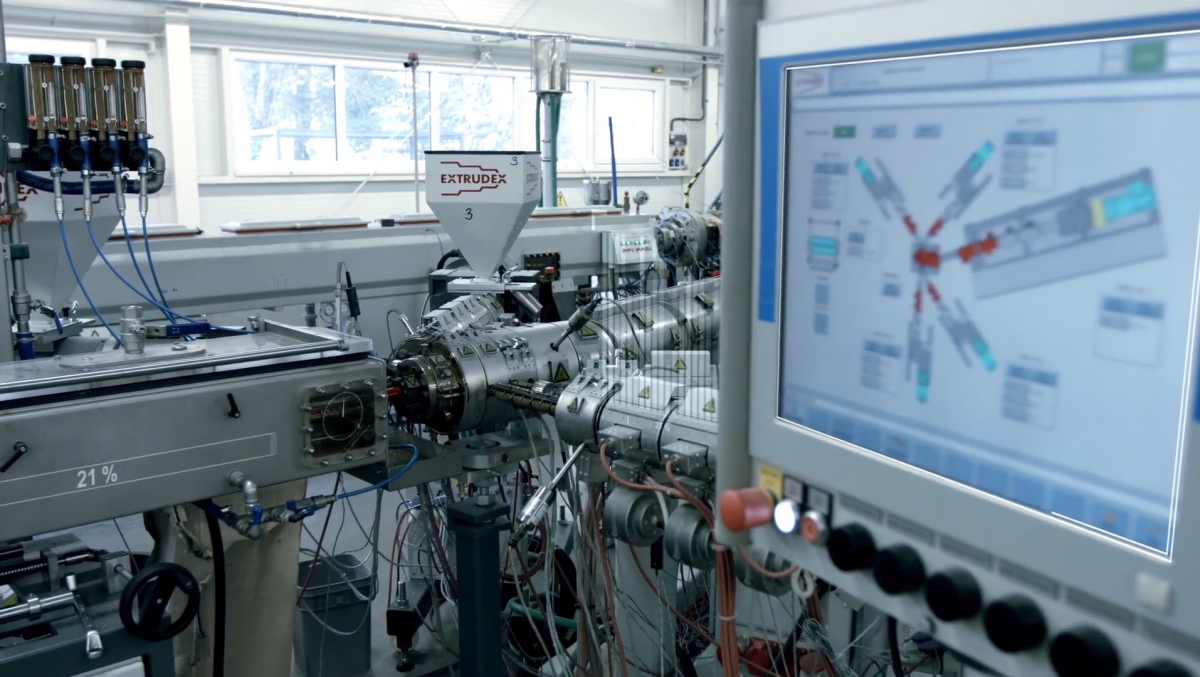

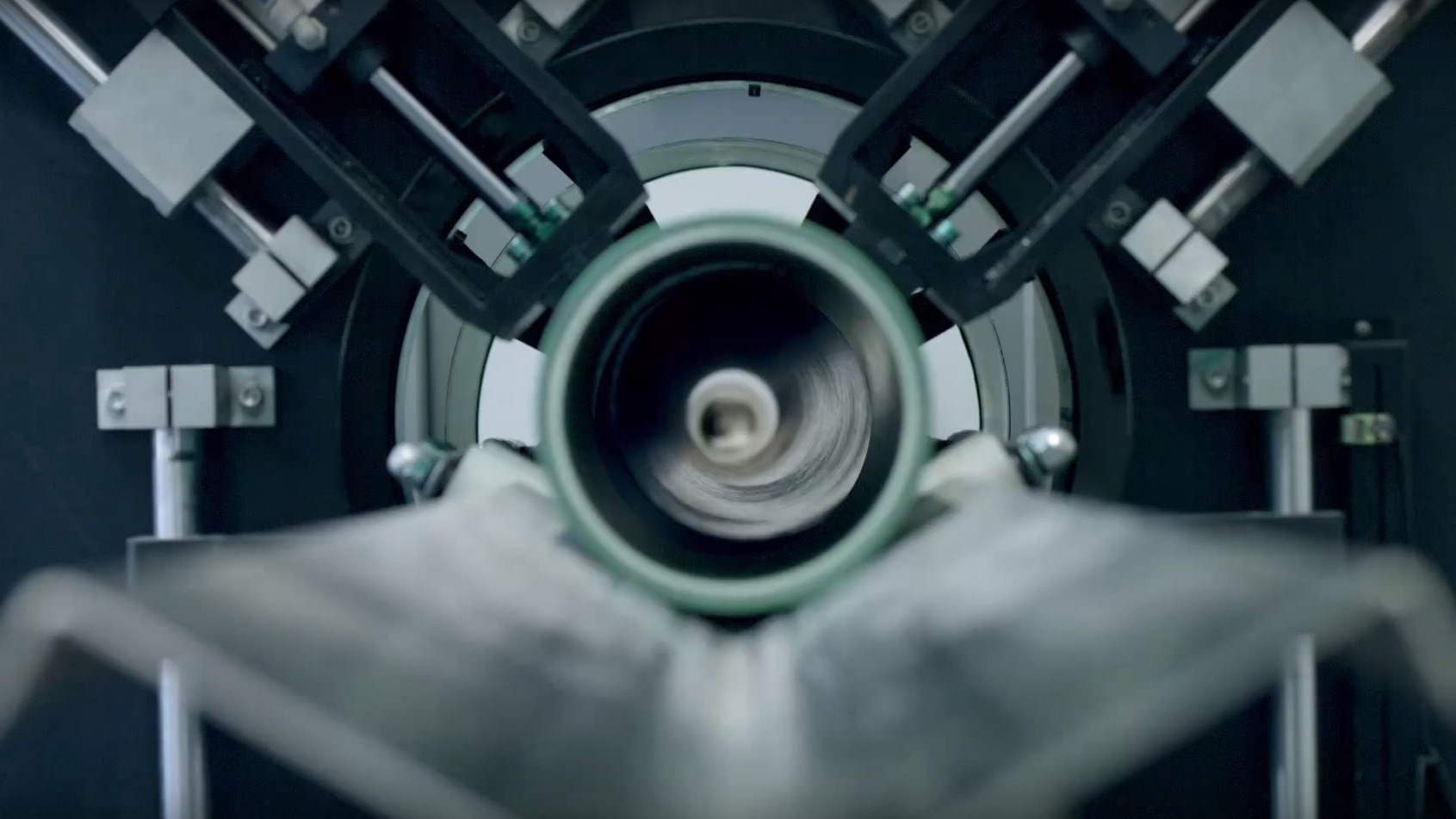

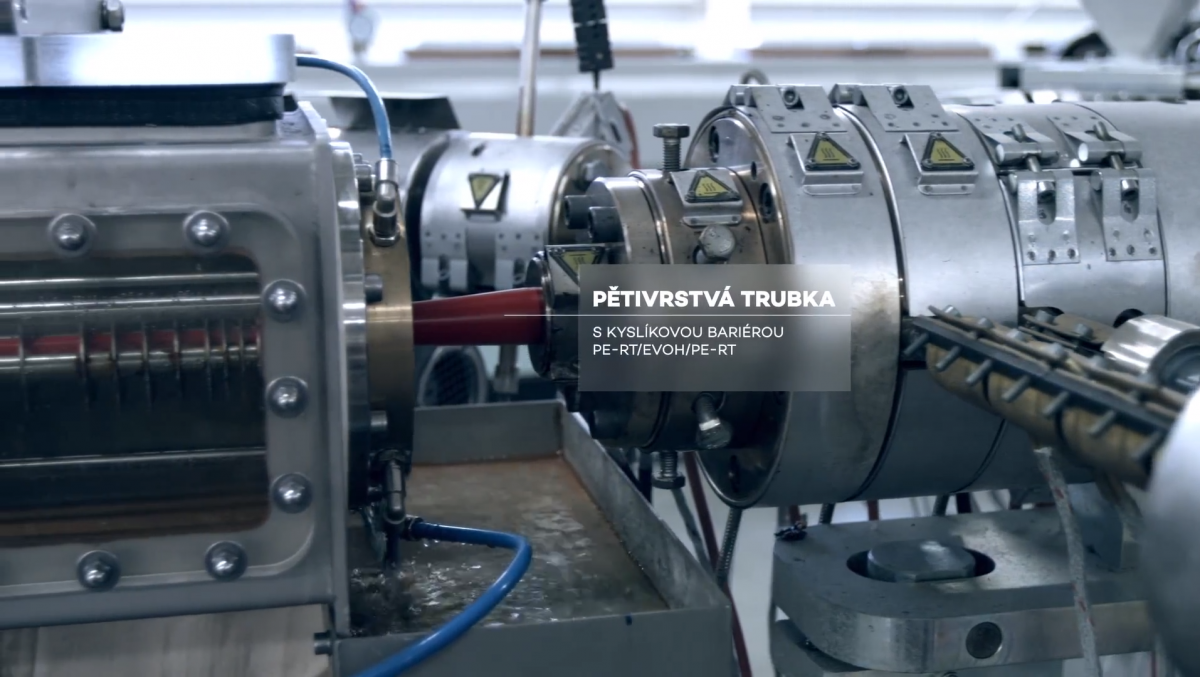

FV - Plast production technologies are the result of our own research and development. We make sure that our products meet the most demanding requirements for modern living. Feel free to come and see how our systems are manufactured.

Our production is fully automated, and is constantly improved and developed based on the latest knowledge. This is also evidenced by the fact that we have invested almost half a billion crowns in the course of the last years.