USE OF THE SYSTEM

System FV AQUA PPR and PP-RCT enables distribution implementations in residential houses, administrative and public buildings, in industry and agriculture. It is intended for delivery of cold and hot water and also for central heating, provided that the prescribed rules are met. It is necessary to select suitable kind of pipes with corresponding parameters of limit operating temperature and pressure. The system FV AQUA offers pipes PPR, PPR-RCT HOT, PP-RCT UNI, FASER and STABIOXY.

The system can also be used for air distributions. A possibility of leading other liquids, gases or solids needs to be assessed individually in every particular example.

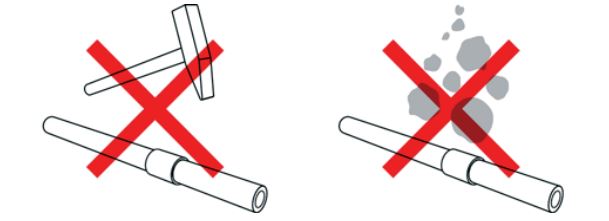

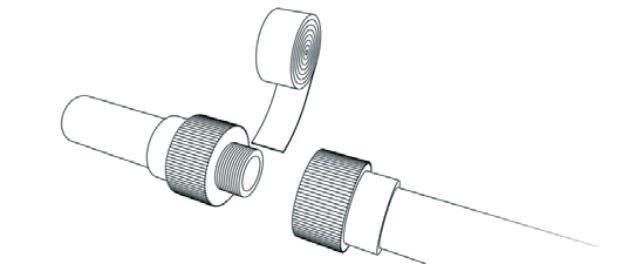

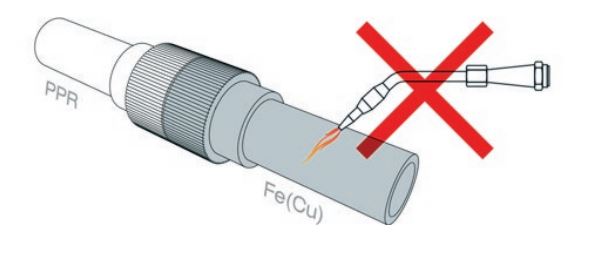

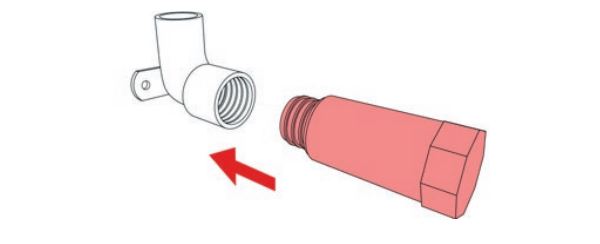

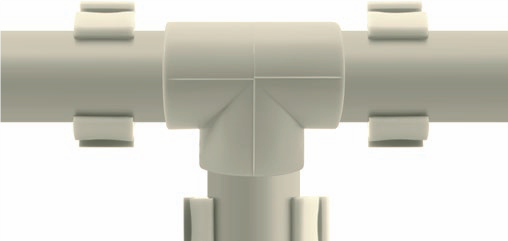

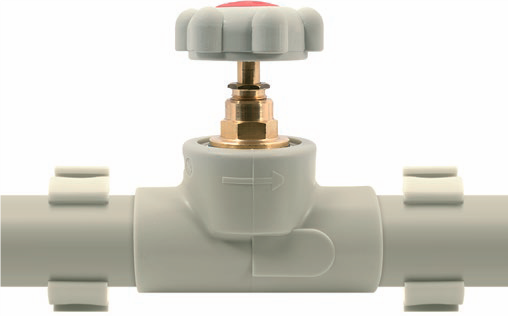

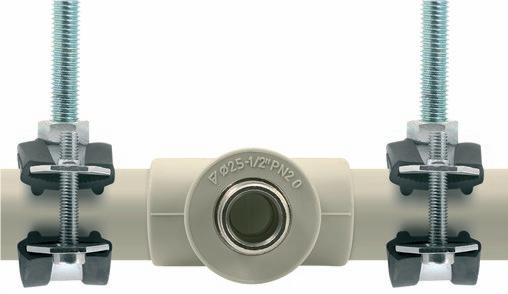

All pipes can be connected by a complete range of PPR pipe fittings by a polyfusion welding (up to the diameter of 125 mm) or by butt welding (diameters beyond 160 mm).

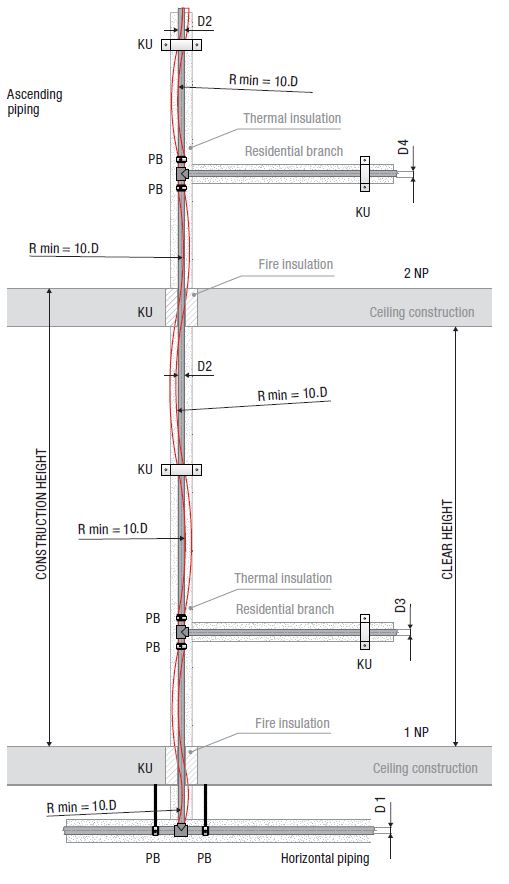

Water distributions

The system can be used for all inner water piping systems (cold drinking water, cold service water, hot water, circulation). An expected lifespan for a plastic piping system is 50 years providing the right material, type of a piping and correct implementation.

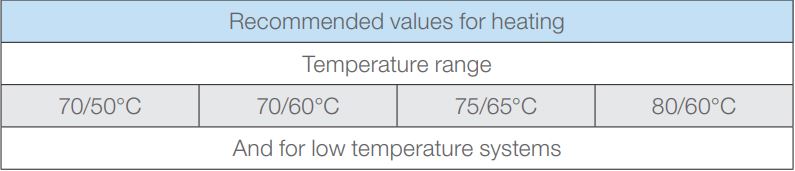

Type of a pipe according to the system of the hot water heating and its temperature regulation is selected by a project architect. In the case of hot water distribution, the expected maximum water temperature at the outflow tap is 57 °C as a protection against scalding, and inside the distributions themselves, there is a possibility of short-term water overheating to higher temperatures (70 °C) at the point of heating due to the hygiene, mainly in order to eliminate pathological organisms.