- Search term must have more than 2 characters.

ASSEMBLY INSTRUCTIONS FOR CONNECTING OF PIPES WITH PIPE FITTINGS FV M-PRESS

Pipe fittings FV M-PRESS are intended for contruction of water and heating distribution systems for multi-layer pipes FV MULTIPERT-5 and FV MULTIPERT-AL.

FV M-PRESS

- Complete line of first-rate brass pressed pipe fittings for a wide range of uses. Even for the most demanding implementations as in the cases of heating water distribution systems.

- Wide range of diameters from d16 to d63 (according to the type of a pipe fitting).

- Plumber´s union with outer or inner thread, eurocone, a cap nut and plumber´s union to copper distribution systems, connected by pressing or soldering, ensure an easy connection to any other distribution system.

- Floor or ceiling distributors, unique double-circuit distributor with crossing, elbows and T-pieces for connecting radiators for an easy implementation of heating distributions.

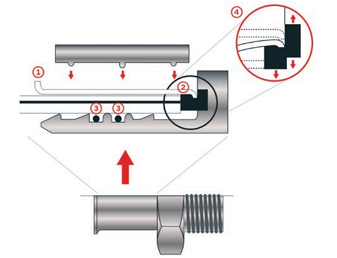

CONNECTING BY PRESS FITTINGS FV M-PRESS

Pipe fittings FV M-PRESS are fundamentally based on perfect sealing of impressed link by means of specially shaped grooves, rubber o-rings and adjustable placement of a cup.